Meghna Cement Mills PLC.

Meghna Cement Mills PLC.

BIR Cement has the most modern laboratories in its both plants. Samples from each batch are tested on hourly and daily basis for quality assessment. These quality parameters are strictly monitored from production to delivery process. The best quality raw materials, modern production technology and advanced testing equipment enable BIR Cement to maintain quality consistency.

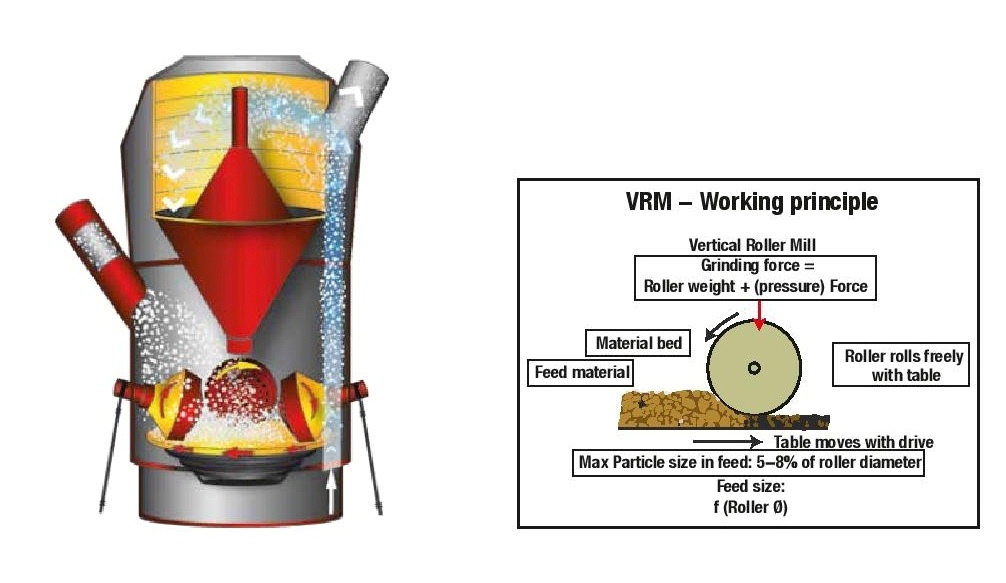

The plant operation is very essential to be at the constant and optimal condition. And best quality raw materials and advanced technology can assure that. Vertical Roller Mill (VRM) is the most advanced technology in cement production method. It provides high fineness and better Particle Size Distribution (PSD) of the finished product, ensuring the better blending properties and faster setting of Bir Cement. VRM is environment-friendly, emitting less CO2 and consuming less energy.

Latent hydraulic and pozzolanic properties in Bir Portland Composite Cement ensures high strength of concrete. Usually, concrete gains strength up to 90 days, whereas Bir Portland Composite Cement gains strength up to 10 years. Bir Cement has the most modern laboratories in its both plants. Samples from each batch are tested on hourly and daily basis for quality assessment. These quality parameters are strictly monitored from production to delivery process. The best quality raw materials, modern production technology and advanced testing equipment enable Bir Cement to maintain quality consistency.

Pozzolanic materials are added as supplementary cementing materials with clinker in order to enhance the performance of the hydrated cement. The pozzolanic reaction between pozzolan and lime generates less heat, resulting in reduced thermal cracking of concrete.

The concrete cast by BIR Portland Composite Cement achieves increased resistance to sulphate and chloride attack. This enables the concrete to become more durable and to protect the reinforcement.